For protective masks, add silver

Text block one Heading link

Two-plus years into the COVID-19 pandemic, supplies of medical-grade masks have increased, but there is still a demand for high-quality, reusable masks to help protect health care workers and populations across the globe.

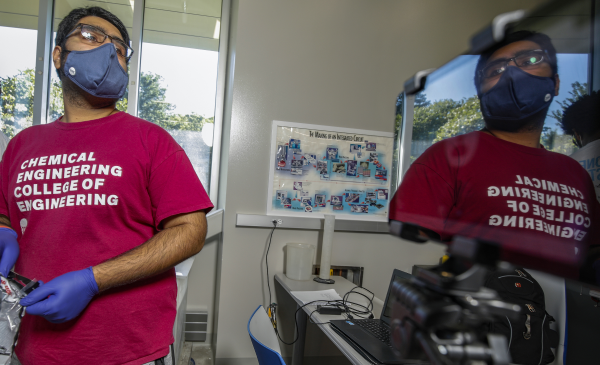

Richard and Loan Hill Biomedical Engineering Department Professor Christos Takoudis, with Professor Cortino Sukotjo from the College of Dentistry and their colleagues, investigated new ways to create N95 masks that are highly protective and retain that protective ability even after having been washed, so they can prolong their lifespans and cut down on costs. And they did so by spinning in tiny pockets of silver.

Traditionally, most N95 masks are made of a material called polypropylene, a synthetic plastic fiber. They also can include other materials such as aluminum, polyurethane, steel, and rubber.

The scientists used atomic layer deposition to imbed the filter of an N95 mask with tiny nano-islands of silver. They then exposed the masks to antimicrobial tests, finding a 76% reduction in bacteria content after 24 hours of biofilm development on the mask surfaces. The study showed there is far less concern about likely toxicity with the use of the novel nano-islands versus different techniques for adding silver to a mask.

“Based on our preliminary results, it does not seem to be difficult to have silver nano-island treated masks that can indeed stand up to being washed and still maintain their protective ability,” Takoudis said.