Manufacturing Off World

UIC launches in-space manufacturing research center with $4.65 million NASA grant

Deep space exploration is among the most complex human endeavors, and the future of these expeditions hinges on solving many challenges. One of the tasks is solving the constraints of resources and how the astronauts will get the materials they need if a part breaks or malfunctions. The idea of waiting for the part to be delivered from Earth is a non-starter, especially in the case of an emergency where the astronauts’ lives may be at risk.

The solutions to these roadblocks are being developed by engineers using creativity in advancing technologies to ensure space explorations will be safer and more efficient.

At UIC, Yayue Pan, associate professor of mechanical and industrial engineering (MIE), is leading a team of engineers as they take on this mission with the NASA MIRO Center for In-Space Manufacturing (CISM-R2): Recycling and Regolith Processing. The research center specializes in developing in-space manufacturing techniques through recycling and utilizing available materials found in space to support sustainable space exploration.

The college launched the center with the support of a NASA grant of more than $4.6 million from its Minority University Research and Education Project Institutional Research Opportunity (MIRO). The program is focused on helping institutions raise their technological bar and enhance their capabilities and infrastructure to become more competitive in research, which opens doors to valuable experience and opportunities.

Over the next five years, the UIC team will focus on four main research areas: recycled/regolith-based composites discovery and manufacturing led by Pan, director of CISM-R2 center; Architected design led by Assistant Professor Jida Huang; Non-destructive evaluation and characterization led by Civil, Materials, and Environmental Engineering Professor Didem Ozevin; and life cycle assessment and sustainability, led by Professor Lin Li.

Recycled/regolith-based composites discovery and manufacturing

“A major challenge in space exploration is the limited availability of resources,” Pan said. “Through this NASA MIRO Center, we aim to address this limitation by developing advanced manufacturing technologies to enable the recycling of waste materials in space and the processing of planetary regolith.”

Regolith is a blanket of loose deposits covering solid rock. It includes dust, broken rocks, and related materials found on Earth’s Moon, Mars, some asteroids, and other celestial bodies.

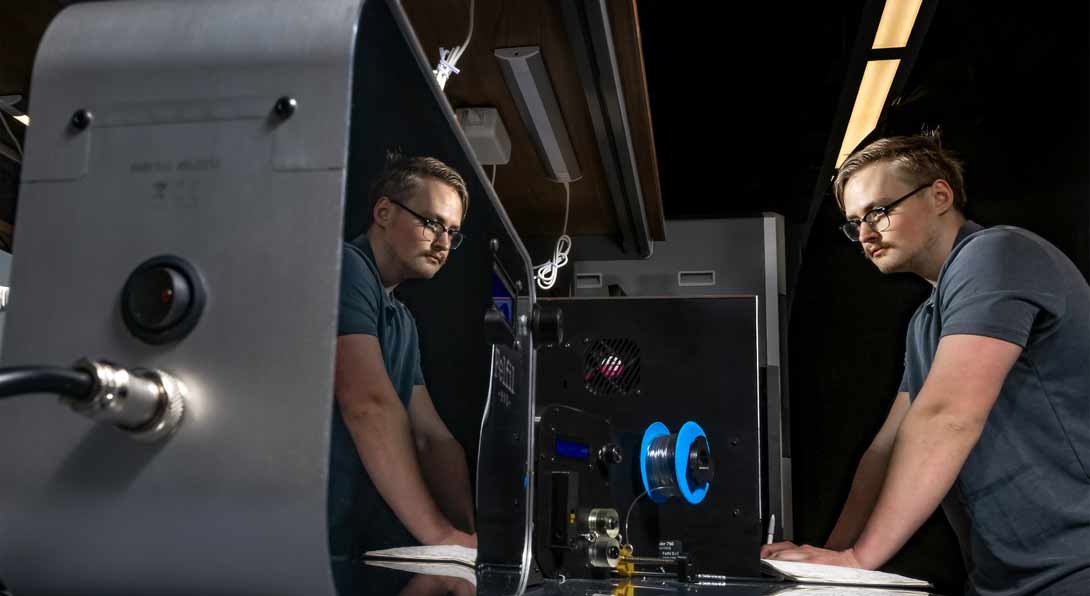

Pan focuses on developing advanced manufacturing technologies. Her research addresses key challenges in additive manufacturing, including limited resolution, inferior material property, and restricted material options. Her work aims to transform additive manufacturing into multi-material advanced manufacturing technologies capable of producing objects with spatially varying material compositions, intricate multiscale features, and programmable material intelligence.

While there are similarities between her current research and NASA research, the in-space context presents unique challenges due to resource scarcity and extreme environments.

“Our team, with its combined expertise, will build on proven in-space manufacturing technologies endorsed by NASA and pioneer new techniques and knowledge to expand NASA’s in-space manufacturing capabilities,” Pan said. “The research will explore new composites based on recycled materials and regolith, architected designs for exceptional properties, non-destructive evaluation methods for space-fabricated parts, material-structure-process co-design, and sustainability assessments.”

Architected design

Huang is no stranger to working with NASA. He has previously worked with NASA Marshall Space Flight Center (MSFC) on two NASA-funded projects, and the technologies developed from the collaborations are extended to this center’s research.

For this project, he is responsible for design research, including materials and structures fabricated for extreme manufacturing within the context of in-space exploration.

“My goal is to achieve design automation for the architectures of regolith composite materials. Materials-structure-properties have entangled complex relations,” he said. “The traditional design process is a slow, iterative “design-build-test” fashion consisting of iterations of expensive multi-physics simulations, and significant human effort, which results in huge development costs.”

His research aims to overcome this challenge by leveraging generative artificial intelligence – specifically, geometric AI – to expedite the design process. He wants to leverage the targeted performance requirements so AI algorithms can automatically generate optimal materials and structure designs.

Jida Huang

Many missions within NASA – such as NASA’s Additive Manufacturing, Artemis, Lunar and Earth Orbit missions, and beyond to Mars and Solar System Exploration as listed in the 2020 NASA Technology Taxonomy report – require swift design for prototyping and this research provides a foundation for extreme design to support in-space applications.

| Mechanical and Industrial Assistant Professor

Non-destructive evaluation and characterization

Ozevin’s research will focus on the mechanics and non-destructive testing of the parts manufactured in space to ensure they are high quality.

“NASA is very much interested in non-destructive evaluation,” Ozevin said. “When it comes to 3D printed parts, there are some uncertainties because of the surface roughness and different kinds of defects than typical cast materials. We’re going to explore different techniques to ensure that we assess the quality of the material before it’s put in use.”

With lives at stake, it’s crucial to ensure the material testing is accurate and that the printed parts can survive in space. Unlike parts made to be used on Earth, the researcher has to consider a completely different environment with different temperatures and, in some cases, different radiation conditions.

“We are definitely going beyond traditional engineering. We are a plastic generation, and recycling plastic can also be helpful for Earth,” she said. “Working on something for space is everybody’s dream. I think this is humanity’s next adventure.”

Ozevin is the liaison to The American Society for Nondestructive Testing Inc. (ASNT), a partner organization supporting research and education activities.

It is the world’s largest technical society for non-destructive testing professionals. It provides a forum for exchanging technical information, educational materials and programs, and standards and services for qualification and certification.

As a partner, ASNT is interested in helping Ozevin and the UIC team update the curriculum through feedback, promoting student recruitment efforts, connecting UIC CISM students with industry for understanding real-life problems and mentoring, participating in-space non-destructive testing workshops organized by UIC, and disseminating collaborative work and outcomes.

Didem Ozevin

Working on something for space is everybody’s dream. I think this is humanity’s next adventure.

| Civil, Materials, and Environmental Engineering Professor

Life cycle assessment and sustainability

As an industrial engineer, Li is focused on the life cycle assessment of products and processes and the environmental sustainability of additive manufacturing processes.

“I will be working with graduate and undergraduate students to develop an inventory analyzing material shape, weight, and production environment for environmental impact characterization,” said Li, the DOE Industrial Assessment Center director at UIC.

In addition, he will develop a new course on Sustainable Design and Manufacturing to endorse environmentally responsible design and material reclamation in manufacturing. He will be working with an intern to support energy assessments of additive manufacturing processes for space applications.

The UIC researchers are partnering with Northwestern University, Northern Illinois University, and the NASA Marshall Space Flight Center. The collaborative effort extends to government, industry, and society organizations, including the Chicago mHUB, Contour Crafting Corporation, and The American Society for Nondestructive Testing.

In addition to research, the project will organize workshops, develop course materials, and increase student participation in NASA-related research fields.

“Along with the center, this multi-million-dollar project aims to enhance and sustain UIC’s research and education capability in NASA-related areas and promote the inclusion of underrepresented and low-income UIC students,” Pan said. “The center will offer research internships and assistantships for UIC students and internships at NASA Marshall Space Flight Center in Huntsville, Alabama, and other NASA research centers.”