Turning up the heat on research

Monitoring the health of structures is critical for avoiding disasters. This is especially important when dealing with nuclear reactors where a problem can be devastating.

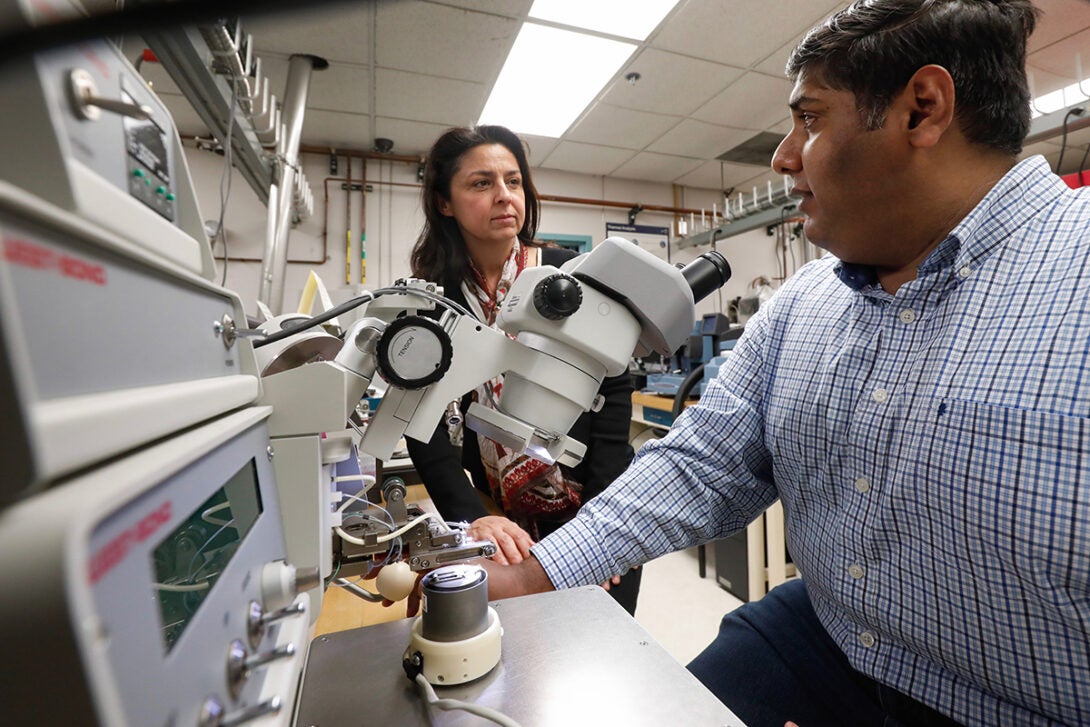

In an effort to provide technology that can withstand high-temperatures, professors Didem Ozevin and Mathew Daly, both of civil, materials, and environmental engineering, are developing a high temperature, multi-functional Micro-Electro-Mechanical-Systems (MEMS) sensors to provide ultrasonic structural health monitoring of piping systems in liquid metal-cooled fast reactors.

The sensor is made from radiation-resistant high temperature materials, which will offer a longer operational lifetime in these extreme environments, and better sensitivity/selectivity to incipient material deterioration.

“There is no such temperature sensor on the market right now,” said Ozevin, who has been a leader in this field with the development of micro-electromechanical systems (MEMS) acoustic sensors for the detection of damage and defects in critical infrastructures.

The capabilities of this sensor are unique with dual functionality, multi-mode selectivity, and the ability to be mass manufactured at low cost. It will be designed to function at 650°C, to be compatible with the typical operating temperature ranges of reactors.

In addition to developing and testing the sensors in labs at UIC, the researchers are partnering with Argonne National Laboratory where they will utilize the Mechanisms Engineering Test Loop for advanced reactors and test the sensors on its piping system.

“These are for advanced reactors and the idea is to operate for ten years without any interruptions. The real-time monitoring will minimize maintenance costs by reducing the probability of forced shutdowns related to failure of critical reactor components,” Ozevin said.

Joining the UIC professors are members of the MISTRAS Group, which specializes in acoustics and ultrasonics and is one of the leading companies in the field of nondestructive evaluation of structures.

In addition to nuclear reactors, the sensors can be used anywhere where there is high temperature. Ozevin said it has the potential to be used in aerospace to monitor areas near the engines.