MIE teams awarded at 27th Annual Engineering EXPO

story title Heading link

Student teams from the Department of Mechanical and Industrial Engineering (MIE) displayed a wide variety of creativity, ingenuity, teamwork and intelligence during the 27th Annual Engineering EXPO on Friday, April 22, at the UIC Forum.

The EXPO featured 119 senior design projects in 21 categories that solved real-world challenges with topics representing majors from all six departments in the College of Engineering. Seven of the first-place awards went to MIE teams, who impressed the guest judges from all areas of the engineering industry. All of the first-place teams were awarded $1,000.

In the Design and Research Studies category, the team of Renan Braulino, Michael Bravo, Ana Escoto, and Matthew Pruett won for their project “Conveyer Design for Graphic Packaging.” The project goal is to develop an automated system able to eliminate labor needs, increase efficiency, and reduce ergonomic issues for Graphic Packaging International in Elk Grove Village, Ill. The team proposed a conveyor system with a design validated through mechanical modeling with an operation simulation and justified through cost and ergonomic analysis. The project reflects real-world teamwork that will directly affect the bottom line of one of the world’s largest manufacturers of packaging goods.

In the Medical Devices I category, Youssef Kirollos, Akshay Vijayaganesh, and Tyler Wilson nabbed first place for their project “Design of an Ultrasonic Nasal Spray for Effective Medication and Vaccine Deposition within Nasal Passages.” The team designed a nasal spray that optimizes parameters like the resonant frequency and atomizing surface area in order to achieve a desired droplet size distribution. Their dose metering mechanism is capable of delivering repeatable quantities of medication, and it is designed to work the same way every time.

In the Mechanical Devices category, Kevin Ahn, Daniel Chan, Omar Guzman, and Steven Vasquez were awarded for their project “Orbital Mixer for Lab Beakers.” The team created a different and more efficient method for the mixing of fluids in a lab setting. Their design is able to mix low-viscosity fluids in a beaker with a max volume of 100 mL with physical rotation of the beaker in multiple axis. Their design runs with the use of one motor connected to a shaft, which is responsible for rotating the beaker along one axis, while a gear mechanism connected to this shaft will be responsible for rotating the beaker along another axis. The innovative design ensures proper mixing of the fluids inside the beaker.

In the Mechanical Processes category, Verne Caro, Jada Jamison, and Eryk Sekiewicz grabbed the top spot for their project “Improving DC Traction Motor Assembly Process.” The assembly of locomotive traction motors is a procedure done by hand and can be potentially dangerous. The students’ intentions were to increase the safety of the technicians by reducing or eliminating crawling under the motor and standing on top of the table along with increasing overall productivity by reducing the dependence of overhead cranes. The design consists of an improved armature alignment method that eliminates the need for workers to be placed in danger and the use of heavy duty lift tables improves ergonomics during assembly. The design also keeps the costs and complexity at a minimum.

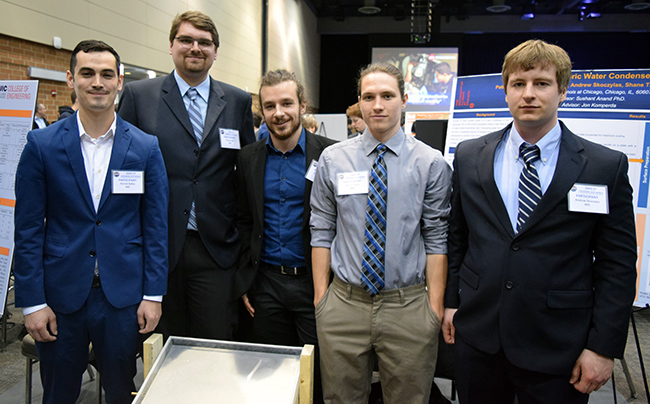

In the Mechanical Product I category, Patrick Bailey, Daniel Budolak, Thomas Roe, Andrew Skoczylas, and Shane Taylor triumphed with their project “Atmospheric Water Condenser.” The team’s project harvests water from the atmosphere as an alternative and viable method for obtaining clean water. The objective is to create a working water condenser that improves upon existing passive water condensers that naturally collect water at night, allowing users to collect more water over an extended duration. The design is scalable, it can be transported to water starved regions, and has the potential to address the challenge related to clean water access.

In the Mechanical Product II category, Jimmy Keclik, Alexander Knox, Andrew Lisak, and Robert Miller earned first place for their project “UIC Motorsports Formula SAE Carbon Fiber Monocoque.” UIC Motorsports constructs a race car every year to compete in the Formula SAE competition. In the past, they used a tubular space frame to construct the chassis. For this project, the team uses carbon fiber sandwich panels with a PVC foam core in place of the tubes, which significantly decreased the weight while making it safer for the driver in the event of an impact. The frame requires less specialized labor and lends itself well to more automated manufacturing methods, which reduces errors.

In the Optimization and Production category, Ian Bonadeo, Brenden Jacobs, Jake Karl, and Kevin Summers secured the win with their project “ASHRAE Design Competition.” The fundamental objective of HVAC design is to provide correctly sized heating, ventilation and air conditioning systems for a building. The team used 2-D drawings of a two-story building in Beijing, and the heating and cooling loads were simulated using architectural software. A computer server room with highly specific temperature and humidity requirements is housed in the main building, and another area has an ambulance running periodically indoors throughout the day. In order to accommodate this, a flex exhaust hose and split system was implemented. The building envelope was designed to meet the recommendations of ASHRAE 189.1. After several simulations, an energy efficient HVAC system for the building was designed demonstrating compliance with the latest editions of ASHRAE Standards 55, 62.1, and 90.1.