MIE seniors display innovation at design expo

story title Heading link

Seniors in the Department of Mechanical and Industrial Engineering (MIE) wrapped up two semesters of hard work as they showcased their research, creativity, and skills on April 26 during the 30th annual UIC Engineering Design Expo at the Isadore and Sadie Dorin Forum, 725 W. Roosevelt Road, Chicago.

The expo featured 44 MIE student teams who brought a wide-variety of projects to the expo that impressed the attendees and judges. The students joined more than 700 College of Engineering undergraduates who completed the two-semester Senior Design Course that challenged them to solve a real-world engineering problems.

Award winners

Eleven teams stood out from the competition as they took home awards from the judges, who represented a variety of professionals from the Chicago region and faculty from the College of Engineering.

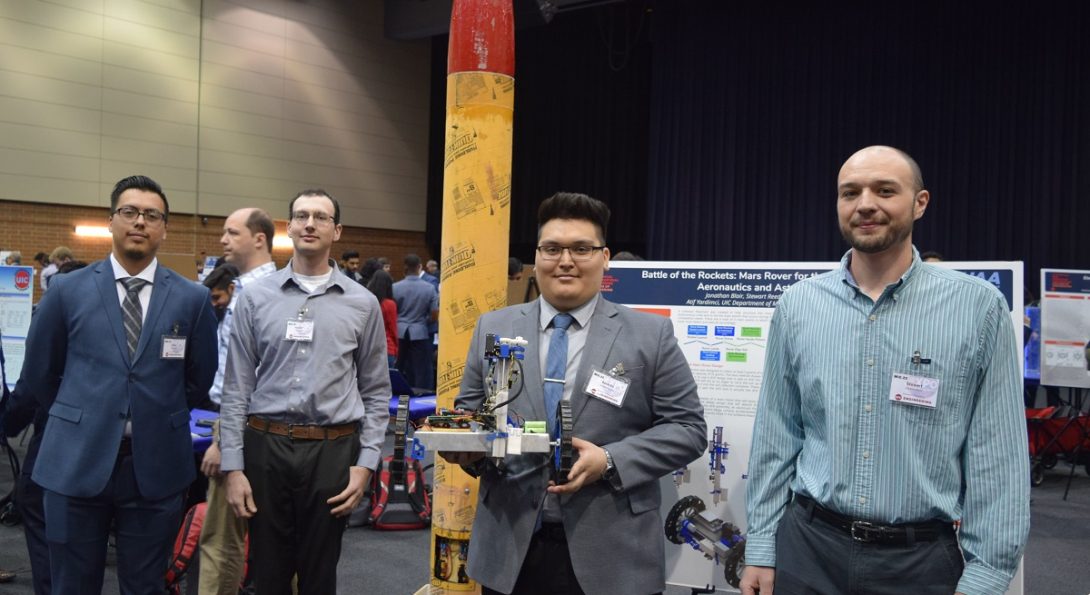

The Aerospace Engineering award went to the team of Jonathan Blair, Stewart Reed, Omar Ron and Gerardo Vargas for their project titled “Battle of The Rockets: Mars Rover for the American Institute of Aeronautics and Astronautics at UIC.”

The team’s rover design incorporates constraints set by the sponsor of the competition, which limits the rover in weight and functionality. Once the rover has launched, deployed, and landed, it is required to autonomously move forward, then take a picture and a soil sample when commanded by a remote control.

The Automotive Engineering award went to the team of Ryan Conley, Froilan Guallpa, Perla Jimenez and Jennifer Rubio for their project titled “Rear Aero Wing Design for SAE Formula Car.”

This project design is geared toward enhancing vehicle performance for SAE International competitions by increasing downforce with the smallest drag penalty possible. Main airfoil and flap airfoil shapes were chosen and then optimized for better performance through Computational Fluid Dynamics analysis. A mounting mechanism was selected to ensure that the wing was properly supported while minimizing drag.

The Consumer Product Development II award went to the team of Klaidi Cako, Marc Duremdes, Marina Youkhana and Hassan Ali for their project titled “Drain Rooter.”

This project presents a new plumbing product that is made to provide a cost effective and reliable solution to unclogging kitchen drains. It is capable of providing suction, irrigation, imaging, and dislodgement, and it allows the end user to perform these functions from a single device.

The Environmental Engineering award went to the team of Ewa Konczewska, Michael Orland, Seth Sheppard, Michael Tegeler and Daniela Cabrera for their project titled “Portable Atmospheric Water Condenser.”

The goal of this project is to create a device that can efficiently condense water in the atmosphere. The device incorporates thermoelectric cooling and has components strategically placed within a housing for the most efficient rate of water collection. Also, it was made as light, portable, and as cost efficient as possible so it can be easily provided to countries in need.

The Industrial Engineering award went to the team of Stephany Ruiz Gonzalez, Jocelyn Rivas, and Joseph Bernick for their project titled “United Airlines & UIC at O’Hare.”

The team standardized United Airlines’ operating system in order to ease how maintenance tools are synchronized within the tool room’s calibration, check-in & check-out, inventory, and shipping & receiving. The improvements will benefit the flow of tools within the home location as well as among domestic outposts.

The Manufacturing Engineering award went to the team of Xun Wang, Paolo Alvarado, Simonas Simulis, and Katie Simonic for their project titled “Automated Spray for Manufacturing Processes.”

The purpose of this project is to improve the efficiency of how a seat panel is joined with covering fabric. The students suggested implementing a conveyor belt system that brings the seating panel underneath the spray path, activates the spray, and moves the seating panel to its next step. The outcome will cut the time for applying glue from 4.5 seconds to 2.5 seconds.

The Mechatronics Engineering award went to the team of Malik Blackman, Mustafa Kanan, Zain Ahmed and Klaudia Swigon for their project titled “Filament Splicer.”

Filament feedstock reels for 3-D printers that do not contain enough filament to complete a print cycle are often disposed. To reduce or eliminate this waste, the students developed a method that would allow two reels of filament to be fused together to form a single reel. Efficiency tests conducted on the final prototype ensured the device met all required criteria and consistently spliced filament.

The Product Improvement award went to the team of Bader Abbas, Guillermo Ortega, Tariq Mdanat, Alexis Estrada and Brian Flanagan for their project titled “Ultima 65 Cutter.” The project goal, in partnership with ACCO Brands, is to improve the Ultima 65 by introducing a mechanism that would automatically cut the sheets of laminate outgoing from the machine after initiating the cutting process. This upgrade eliminates the need for manual cutting, while preserving and protecting important documents.

The Sensor Technology award went to the team of Kent Dixon, Brian Zappa, Alexandro Candelas and Michael Gremillion for their project titled “SAE Baja Data Acquisition.”

This product is the result of UIC’s SAE BAJA team wishing to produce accurate, meaningful data to present during competitions. Research was performed to determine the best sensors to measure suspension travel, vehicle speed, engine output shaft speed, CVT belt temperature, and vehicle rotation about the x, y, and z axis. Data for each sensor will be collected 50 times per second and stored on a microSD card that is attached to the microcontroller.

The Thermal/Fluids Engineering award went to the team of Omar Garcia, Shayan Ranjbari, Mahmoud Hamouda and Paul Nguyen for their project titled “Volumetric Heating of a Flowing Viscous Fluid Using Infrared Radiation.”

For this project, the main application is to reduce the viscosity, droplet size and to atomize the methylcellulose by a spraying nozzle. The proposed solution investigates the use of a radiative heating source which heats the fluid volumetrically and evenly. This is achieved as heat source emits radiation at a constant rate for the time the system is on. When the fluid reaches the nozzle, it has had a significant temperature change which decreases viscosity to the point of successful atomization.

The judges awarded the best prototype award in MIE to the team of Salem Yahya, Sagar Kalra, Khaled Alkhaldy, Abraham Hagos and Rehan Saleem for their “RC Quadcopter” project in the Aerospace Engineering category.

The group designed and manufactured a remote-controlled quadcopter that is user friendly and can be used as a base for various purposes. The team figured out how to program and control the blackboard flight controller chip using a desktop interface, and designed and printed 3-D parts using SolidWorks. The final product is an ideal drone designed for freight purposes and can be easily modified.