Reducing pulp, paper emissions

Introduction

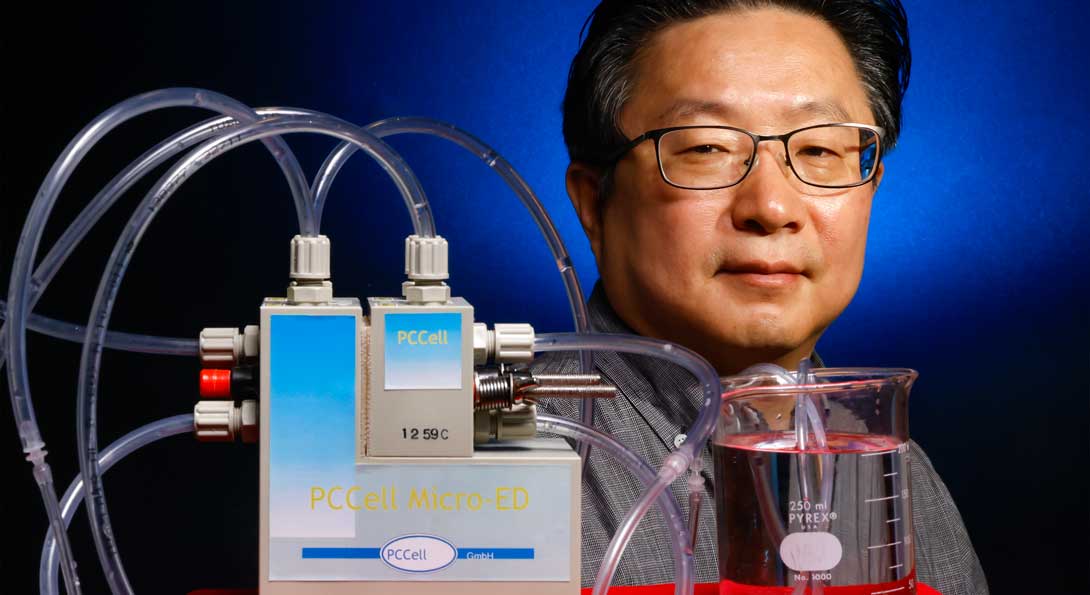

Chemical Engineering Associate Professor Sangil Kim and Professor Brian Chaplin were recently awarded a grant by the Department of Energy’s Industrial Efficiency and Decarbonization Office (IEDO) to support research in reducing the CO2 emissions generated by pulp and paper production.

Pulp and paper are two of the largest industrial sectors worldwide and, thus, have significant environmental consequences. According to the US Environmental Protection Agency, the pulp and paper industry was responsible for emitting 34.9 million metric tons of CO2 in 2021.

Chaplin said their innovative membrane technology can effectively tackle the challenges in decarbonizing the pulp and paper industry.

Working with North Carolina State University, the Rensselaer Polytechnic Institute, and Rayonier Advanced Materials, they are employing a novel bipolar membrane electrodialysis (BMED) system to reduce greenhouse gas emissions, specifically CO2.

In the project, the BMED system replaces the traditional kraft chemical recovery processes of using a recovery boiler and lime kiln in the pulp and paper industry that consume large amounts of electricity and produce large amounts of CO2. In particular, replacing the recovery boiler is crucial for decarbonizing the pulp and paper industry, as it accounts for more than 65% of the total CO2emissions in a mill. This high level of emissions is primarily due to the combustion of dissolved lignin, a class of organic polymers that form cell walls in wood and bark.

Implementing the proposed BMED technology in pulping chemical recovery will allow the elimination of the recovery boiler and lime kiln, which will substantially reduce CO2 emissions. The proposed technology will yield lignin products that can be converted into aviation fuel, contributing to further CO2 emission reduction.