UIC professor looks to the future of electrochemical water treatment

story title Heading link

Despite being necessary for life, water is often not valued as a precious resource until it is in short supply or contaminated. Increasing global population, climate change and crumbling water infrastructure have all threaten this life-sustaining resource and have prompted a University of Illinois Chicago researcher to look at a new, more flexible water treatment model that can adapt to this uncertain environment.

UIC Chemical Engineering Department Associate Professor Brian Chaplin recently published a review article in Accounts of Chemical Research. In his review, Chaplin looked at the advantages electrochemical methods offer over existing water treatment technologies and specific challenges the novel technique faces for broad adoption. The work was published as a part of a special issue entitled “Water for Two Worlds: Urban and Rural Communities.”

Chaplin said there are several kinds of electrochemical water treatment technologies being developed and studied that remove different classes of contaminants such as metals, salt, bacteria and other pollutants. Electrochemical technologies can also produce the necessary chemicals needed for treatment by reactions between water and the electrode surfaces. Therefore, electrochemical technologies eliminate the need to add chemicals that are dangerous to store, costly to transport and may cause environmental pollution.

“You can conceivably design a water treatment strategy that relies on only electrochemical technologies to treat your water, which is the focus of our research,” Chaplin said.

The growing gap between water demand and supply, along with decaying infrastructure, is causing some to question whether the traditional centralized water treatment model, where wastewater and drinking water are treated at centralized plants and conveyed long distances in underground pipes will work in the future.

Chaplin noted in the traditional model all the water in a person’s home, whether they use it to cook or to clean, is transported to one place and treated to the same extent. However, the decentralized fit-for-purpose treatment model focuses on local treatment and distribution. It also calls for water to be treated to the level that is needed for its intended use.

“For example, if you are using it for drinking it has to be very pure, but if you are using it for bathing, doing laundry or washing dishes, there may be a different quality standard,” Chaplin said. “For example, you don’t need pristine water if you are just flushing your toilet with it.”

Electrochemical technologies could represent an important piece of the puzzle for the decentralized treatment model because they are flexible in terms of treatment and can be scaled to fit regional needs.

“I think electrochemical treatment has a place in this distributed model because it operates by using small modules,” Chaplin said. “So, when you are scaling up electrochemical treatment, it’s done by simply adding more modules to the whole design.”

In his review, Chaplin also discussed the challenges and limitations electrochemical water treatment researchers need to overcome before commercial technologies can be developed.

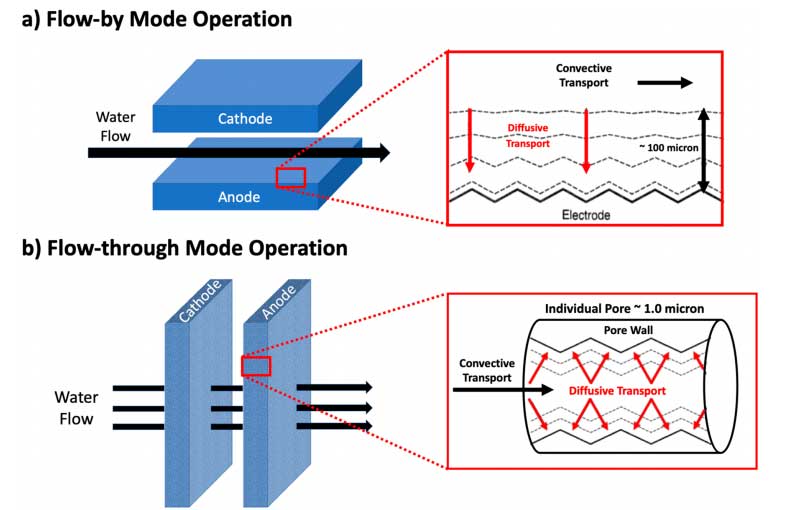

One of the primary challenges Chaplin identified is the cost of manufacturing electrodes, especially state-of-the-art versions, which are needed to spark the chemical reactions in the water. Compounding this problem is the fact the electrodes also have a low active surface area, so a given system would require many expensive electrodes to meet the treatment objectives. Chaplin stressed future research should focus on finding lower cost alternatives and methods for creating high surface area electrodes.

Chaplin’s goal in the near term is to start to pilot test these electrochemical systems for different applications.

To aid in these efforts, Chaplin recently received two grants totaling more than $800,000. These include a $75,000 grant from the National Association of Surface Finishing to test an electrochemical destructive treatment strategy for the remediation of per- and polyfluoroalkyl substances (PFASs). These substances are chemicals that have unique properties that impart water and oil repellency and have historically been used as coatings for consumer packaging, textiles and metal plating in a variety of industries.

Chaplin added the overarching goal of his work is to use a cost-effective reactive electrochemical membrane (REM) to remove PFASs from synthetic electroplating wastewater. Chaplin’s lab developed the patent-pending REM technology, which uses a conductive ceramic electrode material equipped with micron-sized pores to electrochemically oxidize or reduce contaminants.

He also received a Strategic Environmental Research and Development Program grant for $749,000 to look into the economic and technical feasibility of using REMs to treat wastewaters produced by the munitions manufacturing process. The project could give the scientists and the Department of Defense (DoD) a better understanding of how electrochemical technologies can be used for wastewater treatment of DoD priority contaminants.

“We have done a lot in the lab, but until you get out and see the challenges in a specific industry, there are still a lot of question marks whether the tech is going to work and if it actually is well positioned for that application,” Chaplin said.

For more information go to Chaplin lab’s website at https://chaplinslab.wordpress.com/.